- Auxiliary Lights

- Light Bars

- Fog/driving Lights

- Underhood/rock Lights

- 3rd Brake Light Solutions

- Back Up Lights

- Other Auxiliary Lighting

- Shop All

Stock

Category

Brand

Rating

Price

Stock

Category

Brand

Rating

Price

We couldn't find any results

- Use different keywords

- Double check your spelling

- Start with something less specific - you can refine your search results later

- Try changing some of your filters below:

Search term:

Everything You Need to Know About Ball Joints and The Best Upgrades

Why Does my Jeep Need Ball Joints?

Jeep and 4x4 owners love many things in life, especially big, heavy tires, suspension lifts, heavy aftermarket bumpers, roof top tents, and more. Unfortunately, this comes at a cost. These components put extra stress on your front end steering that your rig’s factory ball joints simply weren’t built to handle it, leading to premature wear over time. Even without big tires and a lifted suspension, the factory ball joints are known for wearing out incredibly fast.

Worn out ball joints feature all kinds of day-ruining symptoms such as clunking and popping sounds, loose or wandering steering, vibrations, uneven tire wear and much more. It becomes clear just how important ball joints truly are for your 4x4 if you've ever experienced driving a rig with worn out ball joints. That’s why we’re breaking down everything you need to know about ball joints — and how you can strengthen your front end the right way!

What is a Ball Joint?

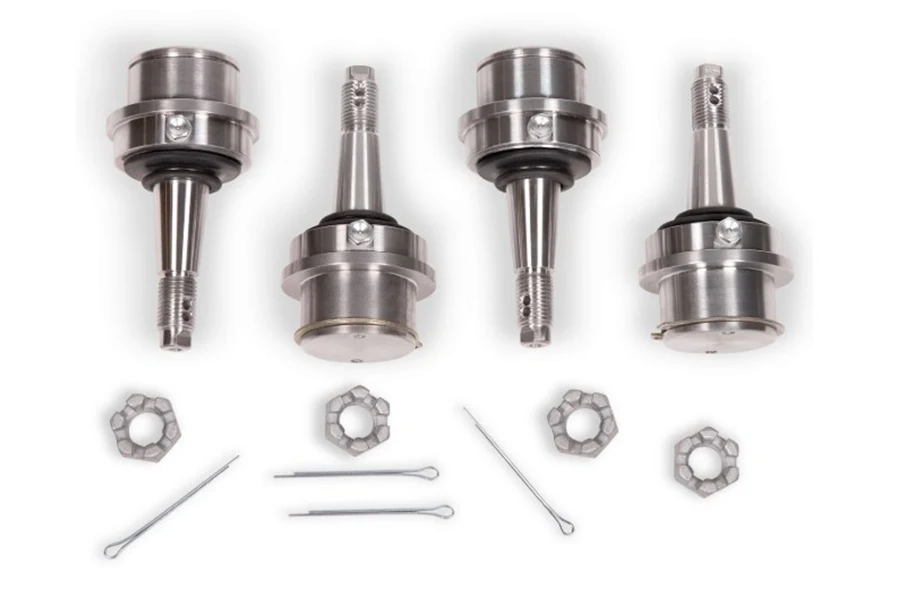

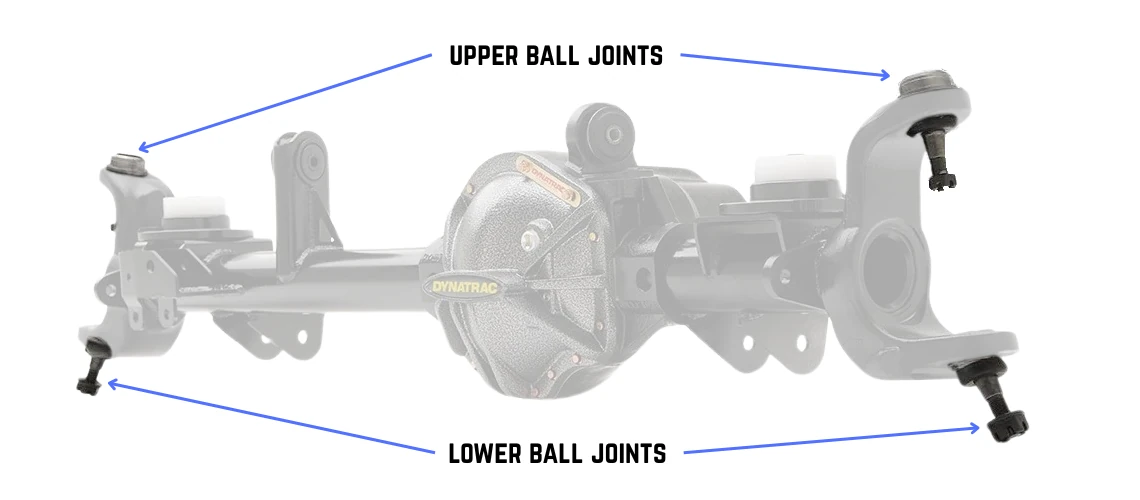

Before we talk about how your Jeep can greatly benefit from a set of aftermarket ball joints, we've got to start with the basics! To start, your Jeep has four ball joints in total — two on each end of the front axle, with an upper and lower ball joint. Not only do ball joints act as a pivot for you steering knuckles, they also deflect side load and hold the majority of your Jeep's weight.

Upper Ball Joint

The upper ball joint is a vital part of your Jeep’s front suspension. It serves as a main pivot point for the steering knuckle and helps handle the side loads created by the tires when turning or navigating rough terrain.

Lower Ball Joint

Lower ball joints also serve as a pivot point in the steering system, but unlike the uppers, they bear most of the vehicle’s weight. Because of this, they’re usually the first to wear out, especially when running larger, heavier tires.

Popular Types of Ball Joints

When looking for upgraded ball joints, you’ll come across a range of options — each with its own features, performance benefits, and price point.

Heavy-Duty OE-Type Replacement Ball Joints

These are the most simple option you can pick from when deciding on aftermarket ball joints. Like their name implies, these are similar to the OE ball joints in that they are not adjustable or rebuildable. However, they do feature heavier duty materials that gives them the added strength to handle the increased load of heavier tires and lifted suspensions.

Who are these ideal for? Heavy-duty OE style ball joints are perfect for those looking for a simple, budget friendly option without any additional features offered by the other types of aftermarket ball joints.

Featured Options

Apex Chassis Front Ball Joint Kit (Non-Knurled): This heavy-duty option features a 4140 chromoly ball stud, a tough 1045 forged steel housing, low friction bronze bearings and a limited lifetime warranty! A zerk fitting is installed to allow for easy greasing of the ball joints to keep them running smoothly.

Synergy MFG HD Non-Knurled Ball Joint Set: Built with a 4140 chromoly ball stud, high strength 1045 steel housing, this option forgoes the factory ball joints frail plastic ball stud liner, opting instead for a metal on metal design. Synergy MFG offers a limited lifetime warranty on their ball joints.

Adjustable Ball Joints

All ball joints wear down overtime, this normal wear and tear eventually starts to loosen the ball joints. Adjustable ball joints main claim to fame is the ability to tighten the ball joints, allowing for the lifespan of the ball joint to be extended.

Who are these ideal for? Heavy-duty adjustable ball joints are ideal for Jeep owners who need extra strength and want the added benefit of extended service life through easy, on-vehicle adjustments.

Featured Option

Teraflex HD Adjustable Ball Joint Kit (Non-Knurled): Teraflex also constructs their ball joints with a 4140 chromoly ball stud and a 1045 steel housing. They use a long-wearing centered metal bushing for smooth operation.

All ball joints loosen up under normal wear and tear, however the Teraflex HD Adjustable Ball Joints can be easily tightened down as it wears, greatly expanding its service life and performance. This option also includes a limited lifetime warranty!

Rebuildable Ball Joints

When a ball joint reaches the end of its life, normally that means it's time to replace them with a brand new set. However with Rebuildable Ball Joints you simply pick up a rebuild kit and can easily return your ball joints to their brand new performance levels. Most rebuildable ball joints can be fully rebuilt without the need to remove the ball joints from the axle housing, making for an easy rebuild!

Who are these ideal for? Rebuildable Ball Joints are the perfect choice for those who want heavy-duty ball joints and don't want to have to completely replace their ball joints when they reach the end of their service life.

Featured Option

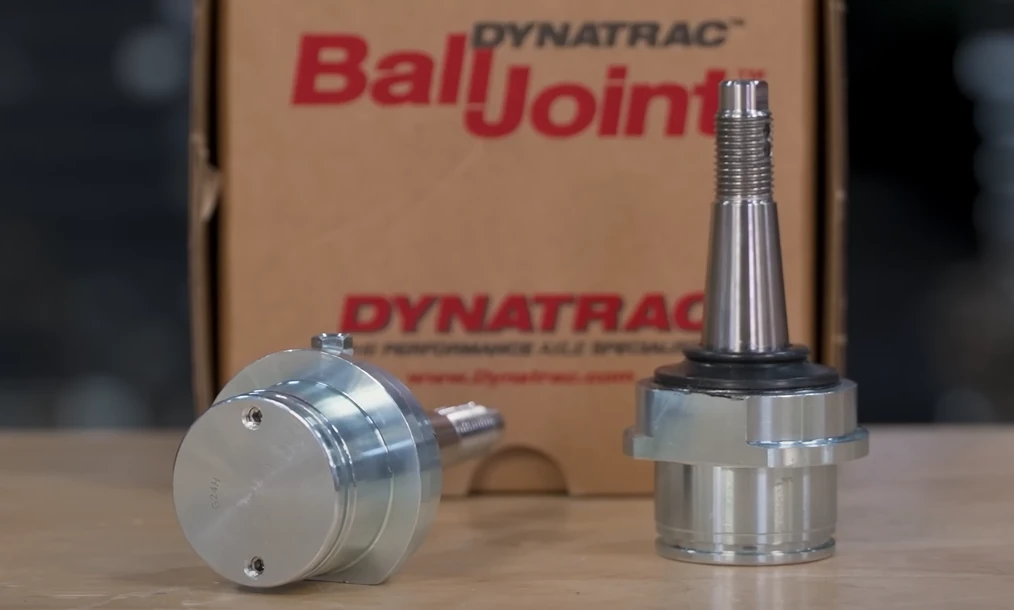

Dynatrac Ball Joint Kit w/ Install Tool Package: The Dynatrac Ball Joint kit features heat-treated 4340 chromoly center studs, held in with a heat-treated billet body. Rather than a ball stud, the Dynatrac uses a two piece stud and spherical bearing. For smooth operation, Dynatrac uses a teflon liner for the spherical bearing, built to military specifications.

What makes this kit special is the ability to fully rebuild the ball joints without needing to remove the ball joints from the axle. This option also features a 1-year warranty.

Adjustable and Rebuildable Ball Joints

Adjustable and rebuildable ball joints offers the most amount of features for upgraded, heavy-duty ball joints. You can not only adjust and tighten these ball joints as they wear to extend their lifespan, but also fully rebuild them to restore brand-new performance.

Who are these ideal for? Adjustable and rebuildable ball joints are ideal for Jeep owners who want a long-term solution. With the ability to extend service life through adjustment and fully rebuild them when they wear out, this option lets you get the most from a single set of ball joints.

Featured Option

Metalcloak Baller Joints (Full Set): Built with a heat-treated 4140 chromoly ball stud and a 1045 steel housing, and hardened S7 steel tool races, the Metalcloak Baller Joints are truly heavy-duty. As the ball joint wears under normal use, you can easily adjust these ball joints to tighten down, thus extended service life and performance. Additionally, these ball joints are fully rebuildable so once they've reached the end of life, you can rebuild them and regain like-new performance.

This is the ultimate ball joint option for those who want maximum strength and a fully rebuildable and adjustable design to get the most out of their ball joints. Best of all, they look pretty bling with that strong, gold zinc finish.

Want a closer look at the ball joints featured in this blog? Checkout our YouTube video!

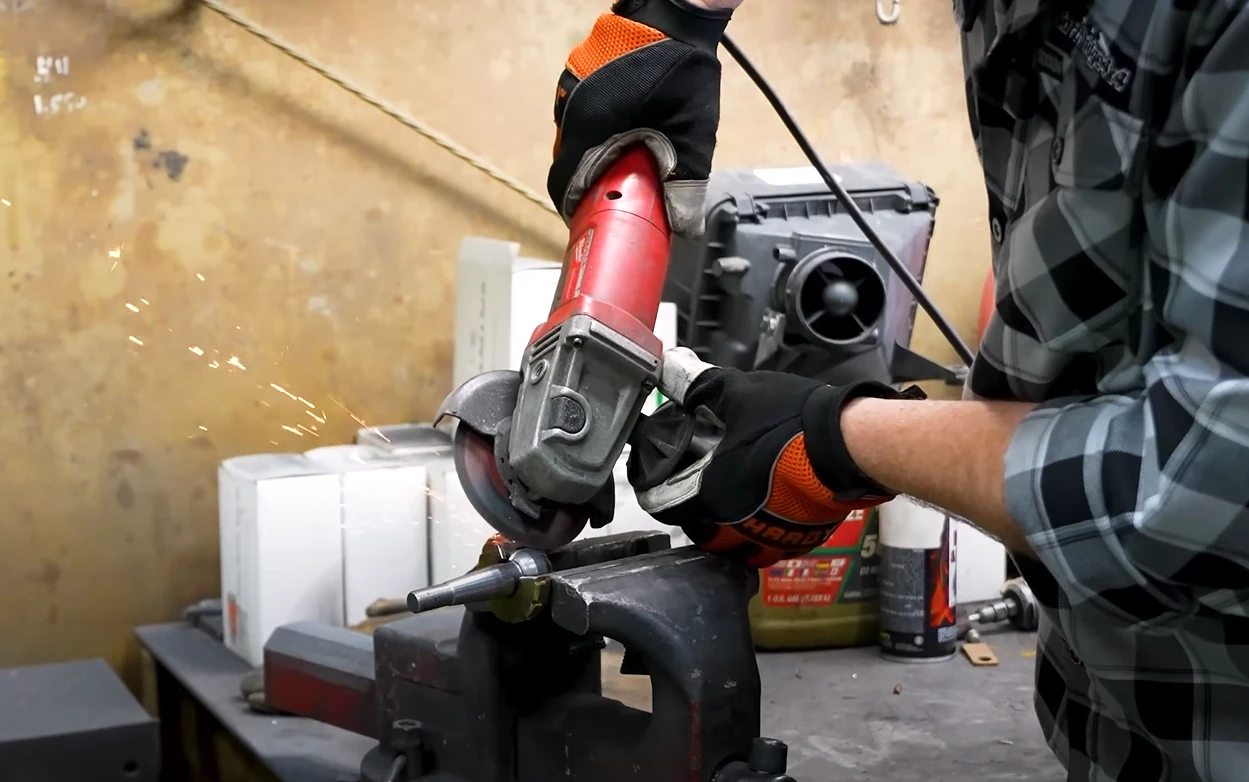

For a deeper dive on each ball joint featured in the blog, and to see Tech Tim cut into a ball joint with a cut-off wheel, check out our YouTube video! Tim walks us through the different designs of each ball joint, explains what sets them apart, and gives us an inside look—literally—at how these ball joints are built and why it matters for your rig's performance and longevity.

Featured Ball Joints

Click Here to view our entire selection of heavy-duty Ball Joints!