- Auxiliary Lights

- Light Bars

- Fog/driving Lights

- Underhood/rock Lights

- 3rd Brake Light Solutions

- Back Up Lights

- Other Auxiliary Lighting

- Shop All

Stock

Category

Brand

Rating

Price

Stock

Category

Brand

Rating

Price

We couldn't find any results

- Use different keywords

- Double check your spelling

- Start with something less specific - you can refine your search results later

- Try changing some of your filters below:

Search term:

Keep Your Jeep Driving Straight: Must-Do Front End Inspection Checklist

Got a rough riding Jeep? Chances are it's time to do a front end inspection on your Jeep's steering components! Luckily performing a front end inspection is a simple process that can be done at home with basic hand tools. Whether you're a first time Jeep owner or a seasoned off-road veteran, we've got the tips and tricks to keeping your Jeep handling its best on the highway and the trail.

Tools Needed

-

Socket Wrench

-

Metric Socket Set

-

Torque Wrench

-

Large water pump pliers

-

Tire tread depth indicator

#1 Nuts and Bolts

The first step for a front end inspection is ensuring all of the front end components are torqued to spec. Loose components can cause vibrations, steering wander, poor handling and much more, so it's very important to get everything nice and tight!

TIP: Applying paint or a marker across the top of a nut or bolt and onto its mounting surface creates a visual reference line. If the bolt loosens, the line will break or shift, making it easy to spot loose bolts during a quick front-end inspection.

*Note: Torque specs listed are for factory components. If aftermarket components are installed, follow the manufacturers torque values, if listed.

|

|

|

|

Track Bar frame bolt |

52ft. lbs + 115 |

|

Track Bar axle bolt |

52ft. lbs + 115 |

|

Drag Link inner nut (at pitman arm) |

77ft. lbs |

|

Drag Link outer nut (at steering knuckles) |

47ft. lbs |

|

Drag Link adjuster clamp |

34ft. lbs |

|

Tie Rod End Nut |

30ft. lbs plus 125° |

|

Tie Rod End adjuster clamp |

34ft. lbs |

|

Steering Damper Bolt |

50ft. lbs |

|

Steering Damper Nut |

55ft. lbs |

|

Steering Damper Bracket Nut |

55ft. lbs |

|

Upper Control Arm Front Bolt |

41ft. lbs plus 185° |

|

Upper Control Arm Rear Bolt |

37ft. lbs plus 135° |

|

Lower Control Arm Front Bolt |

103ft. lbs plus 145° |

|

Lower Control Arm Rear Bolt |

103ft. lbs plus 145° |

|

Shock Absorber Upper Bolt |

52ft. lbs plus 55° |

|

Shock Absorber Lower Bolt |

52ft. lbs plus 55° |

|

Sway Bar Bolts |

46ft. lbs |

|

Sway Bar Link Upper Nut |

69ft. lbs |

|

Sway Bar Link Lower bolt (Right Side) |

59ft. lbs |

|

Sway Bar Link Lower Bolt (Left Side) |

74ft. lbs |

|

Upper Ball Joint Nut |

55ft. lbs |

|

Lower Ball Joint Nut (initial torque) |

15ft. lbs |

|

Lower Ball Joint Nut (final torque) |

59ft. lbs (Updated from TSB 02-004-21) |

|

|

|

|

Track Bar Frame Bracket Nut |

125ft. lbs |

|

Track Bar Axle Bracket Bolt |

125ft. lbs |

|

Drag Link Ball Stud To Pitman Arm |

77ft. lbs |

|

Drag Link Ball Stud To Knuckle |

63ft. lbs |

|

Drag Link Adjuster Clamp |

26ft. lbs |

|

Tie Rod Ends Ball Studs |

63ft. lbs |

|

Tie Rod Ends Clamp |

45ft. lbs |

|

Steering Damper to Frame |

50ft. lbs |

|

Steering Damper to Tie Rod Nut |

50ft. lbs |

|

Upper Control Arms To Frame |

75ft. lbs |

|

Upper Control Arms To Axle Bracket |

75ft. lbs |

|

Lower Control Arms To Frame |

125ft. lbs |

|

Lower Control Arms To Axle Bracket |

125ft. lbs |

|

Shock Absorber Upper Nut |

20ft. lbs |

|

Shock Absorber Lower Nut |

56ft. lbs |

|

Sway Bar Retainer Bolts |

45ft. lbs |

|

Sway Bar Link Upper Nut |

75ft. lbs |

|

Sway Bar Link Lower Nut |

75ft. lbs |

#2 Track Bar Bushings

Over time, daily driving and off-roading will cause your track bar to wear out, leading to looseness at the bushings. Simply tightening the bolts won’t fix the issue, worn bushings need to be replaced, or the track bar should be replaced to restore proper performance. Inspecting these bushings is an important part of your front end inspection.

How to check for worn out Track Bar Bushings:

- Have an assistant continously steer the steering wheel left to right throughout the process

- Carefully inspect the track bar bushings at both ends, and be sure to keep your fingers clear of any moving parts.

- Check for any movement at each bushing—if the track bar bushing is worn, it will move separately from the mount.

Example of a worn out track bar bushing.

#3 Tie Rod and Drag Link

Each end of the tie rod and drag link uses a ball-and-socket joint, which wears out over time. While it's normal for the tie rod and drag link to rotate in and out, any up-and-down movement at the joint indicates wear—and it’s time for a replacement.

How to Check for worn out Tie Rod and Drag Link:

- Using a pair of water pump pliers, grab the bottom of the joint and the upper mounting arm

- Squeeze the pliers, checking for any up and down movement

- Repeat on all tie rod and draglink ball and socket joints.

Example of a worn out Drag Link Ball and Socket Joint.

#4 Sway Bar and Sway Bar End Links

Be sure to inspect your sway bar and end links for any signs of looseness or wear. If the bushings are worn or cracked, they should be replaced. Also, check that all hardware, especially the end links, is tight and secure. Loose components can negatively affect your Jeep's handling and suspension performance.

How to Check for worn out Sway Bar and Sway Bar End Links:

- Inspect Sway Bar for cracked bushings and check for looseness, tighten as needed.

- Inspect Sway Bar End Links for looseness, tighten as needed.

- Replace worn out bushings

Example of a worn out/loose sway bar end link.

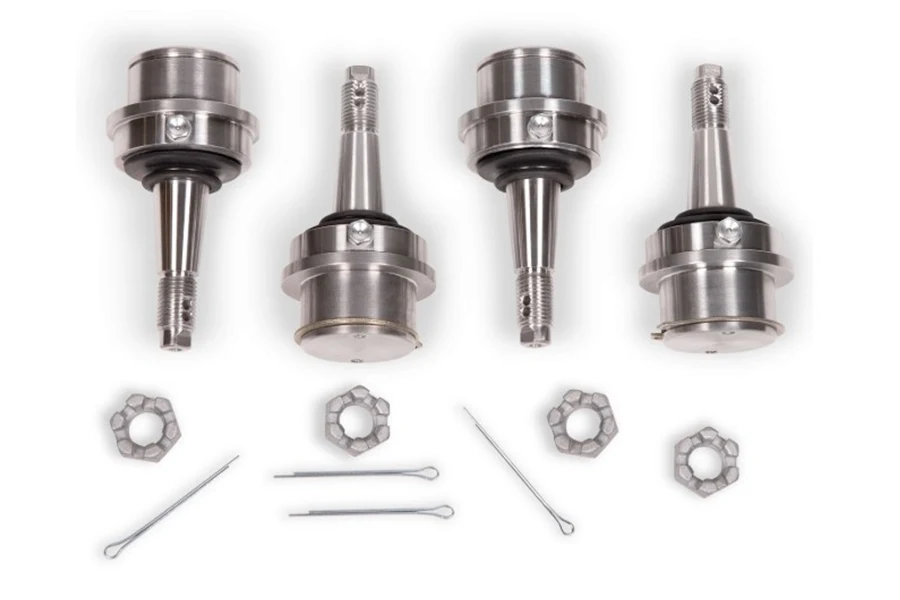

#5 Ball Joints

Inspecting your Jeep’s ball joints is a straightforward process aimed at identifying any up-and-down movement within the ball joint socket. This type of movement is a key indicator of wear and can lead to poor steering response, uneven tire wear, and further suspension issues if not addressed.

How to check for warn out Ball Joints:

- Jack up the Jeep far enough to get a pry bar or 2x4 under the tire of the side you are inspecting.

- Wiggle the tire up and down with the pry bar or 2x4.

- Inspect for up and down movement.

- Replace ball joints as needed.

For more info on the best heavy-duty ball joints, check out our blog post!

#6 Unit/Wheel Bearing Hub

If your Jeep is experiencing wobbling wheels, grinding noises, or vibration at speed, this may indicate a bad unit bearing. Luckily, checking for a worn out Unit Bearing is a straight forward process that can be done quickly and easily.

How to check for a worn out Unit Bearing:

- Jack up the Jeep enough to get the front tires off of the ground

- Grab the tire with both hands

- Rock it back and forth, looking for noticeable movement or clunking

#7 Tires

Ensuring your Jeep's tires are wearing properly and are in good shape is essential to ensure your Jeep is riding and driving its best. There are a few things you need to look out for when inspecting your tires.

How to inspect your Tires:

- Measure the tread depth. A tire, especially an off-road tire, should typically be replaced at 4/32nd of tread depth.

- Look for uneven tire tread wear, this can be caused by improper tire inflation, alignment issues, failure to rotate tires and more.

- Check for cracks, cuts, buldges or other damage

- Check age of the tire on the sidewall, the last four digitals of DOT code represent the week and year the tire was made. For example, 1023 means the 10th week of 2023. Typically, tires should be replaced after six years of use.

Need new tires? Check out our blog post to learn how to choose best off-road tire for your Jeep!

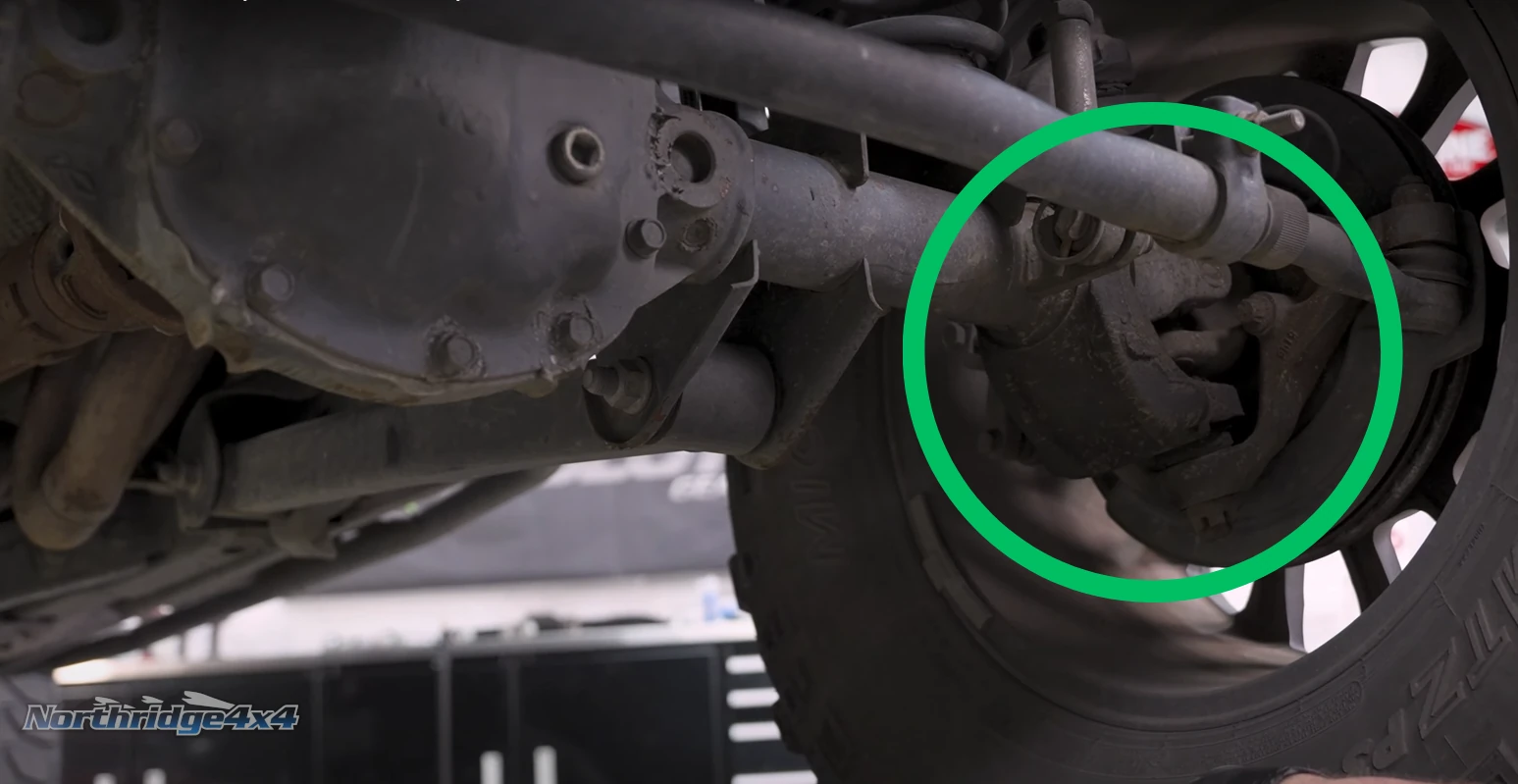

#8 Inner Axle Seal

A common failure point on Jeep Wranglers and Gladiators is the inner axle seal. When this seal begins to leak, gear oil can seep out, pooling on the axle C's and can run down the inside of the tires, often leaving stains where the vehicle is parked. A small leak usually isn’t a major concern, but if too much gear oil is lost, it can lead to more serious issues. Fortunately, checking for a leaking inner axle seal only takes a few seconds.

How to check for leaking axle seals:

- Inspect axle "Cs" for oil

- Gear oil may also flow down sides of wheel/tire

- Replace inner axle seal as necessary

#9 Control Arms

The last time you want to check for your Jeep's front end inspection is the control arms. After checking for tight control arms bolts from step 1 of the inspection, the bushings should be inspected to see if they are loose. Worn out control arm bushings can lead to increased vibrations on the road, clunking noises when hitting bumps, rough ride and more.

How to inspect Control Arm bushings:

- Ensure the Jeep is in Park with the parking break on, on flat level ground

- Have a helper rock the Jeep back and forth by pushing on a front tire side to side.

- Inspect each control arm bushing at each end of the control arm.

- Look for any play in the control arm bushings.

- Replace control arms/bushings as needed.

Example of how to inspect Control Arm bushings.

Check Out Our YouTube Video for More Info!

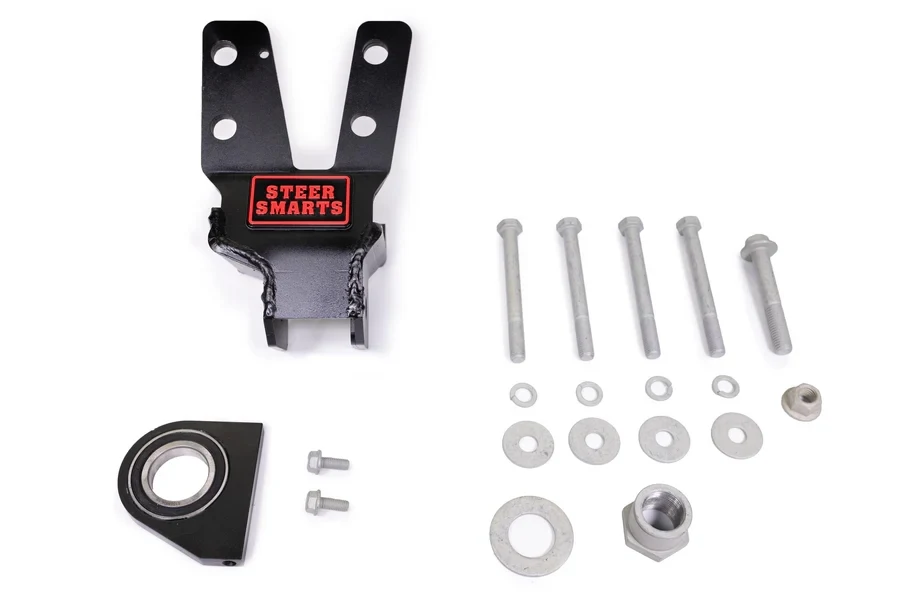

Featured Front End Steering & Suspension Upgrades

Frequently Asked Questions (FAQs)

Q: What are the signs that my Jeep's front-end needs inspection?

A: Common signs include wandering on the highway, uneven tire wear, clunking noises when turning or hitting bumps, steering wheel vibration, or delayed steering response. These symptoms suggest worn or loose components.

Q: How often should I inspect the front-end components on my Jeep?

A: A visual inspection is recommended every 5,000 to 10,000 miles or during routine maintenance like tire rotations. Off-roaders should inspect more frequently, especially after hard trails.

Q: What are signs of a failing unit bearing (hub assembly)?

A: Wobbling wheels, grinding noises, or vibration at speed may indicate a bad unit bearing.

Q: Should I replace components even if they aren't fully failed?

A: Preventative replacement with heavy-duty aftermarket options is smart for commonly worn parts like tie rods, ball joints, and track bars, especially if upgrading tire size or lift height. Factory parts can wear prematurely under added stress.